Success Story: How Zeal Air-Conditioning Solved a Unique Cooling Challenge

Introduction to the Challenge

When Zeal Air-Conditioning received a call from a large industrial client facing a unique cooling challenge, the team knew it was an opportunity to test their expertise. The problem was complex: a specialized manufacturing plant needed an efficient cooling system to maintain precise temperature control across different zones, each with varying requirements.

This wasn't the usual air-conditioning setup. The client required a solution that could handle extreme temperature variations without compromising energy efficiency or production quality. The stakes were high, and Zeal Air-Conditioning was ready to innovate.

Understanding the Needs

The first step involved a comprehensive assessment of the facility. Zeal Air-Conditioning's team visited the site to understand the intricacies of the plant's operations and the specific environmental conditions. It became clear that a one-size-fits-all approach wouldn't work; a customized solution was necessary.

The team conducted detailed analyses of the plant's layout, existing infrastructure, and production schedules. They also consulted with the plant's engineers to gain insights into the precise cooling requirements for each zone. This collaborative approach was crucial in developing an effective plan.

Designing the Solution

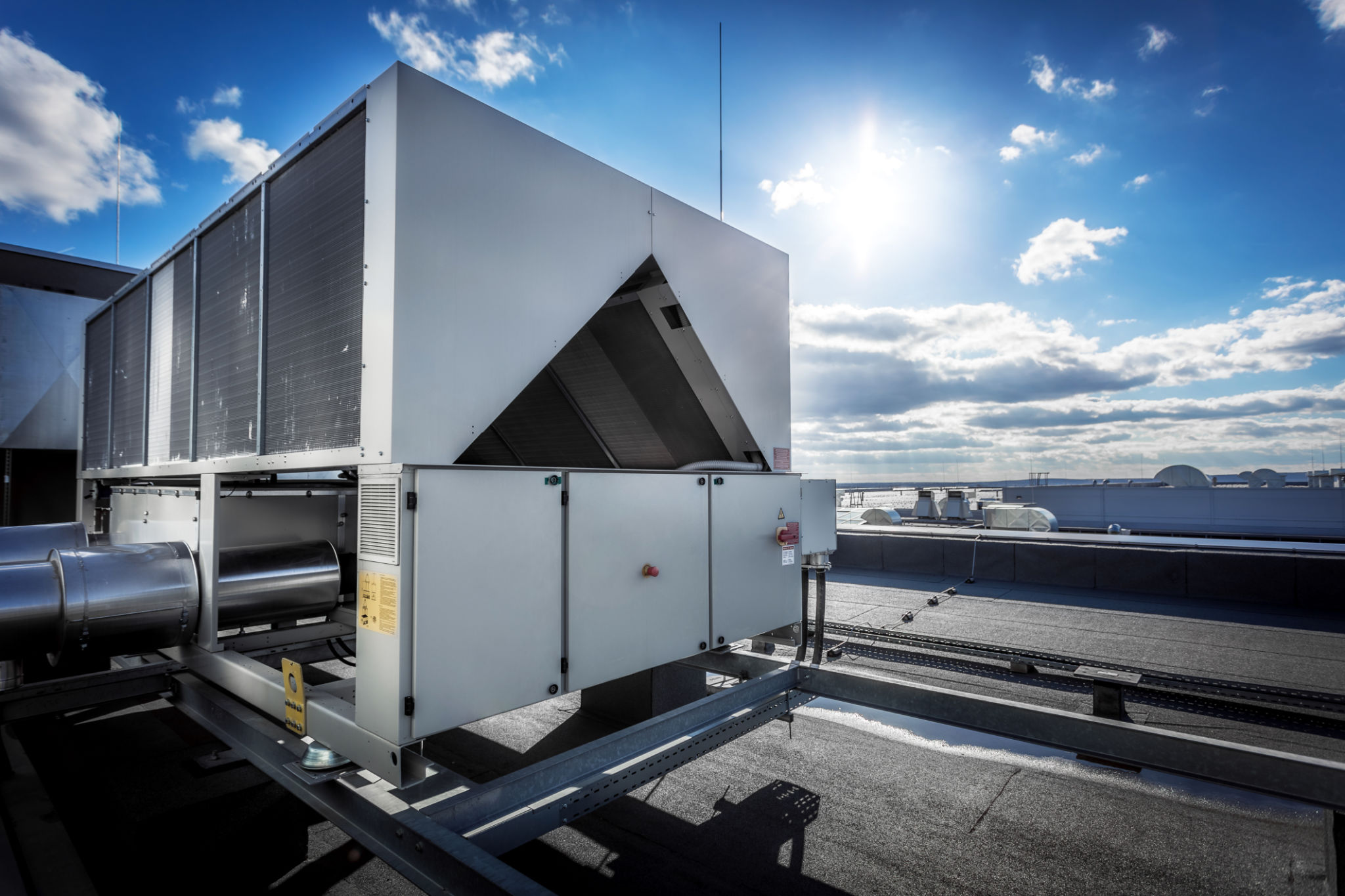

Once the assessment was complete, Zeal Air-Conditioning's engineers set to work designing a bespoke cooling system. The solution involved a combination of advanced HVAC technology and smart automation systems. These innovations allowed for real-time monitoring and adjustments to temperature settings, ensuring optimal conditions at all times.

Key features of the design included:

- Zone-Specific Cooling: Customizable settings for each area to address specific temperature requirements.

- Energy Efficiency: Integration of energy-saving technologies to minimize operational costs.

- Remote Monitoring: Implementation of IoT systems for continuous performance tracking and remote troubleshooting.

Implementation and Testing

With the design in place, implementation began. The installation process was executed with precision, ensuring minimal disruption to the plant's operations. Zeal Air-Conditioning worked closely with the client’s team to integrate the new system seamlessly into their existing setup.

After installation, rigorous testing phases were conducted. The system was monitored under different operating conditions to ensure it met all performance benchmarks. Any necessary adjustments were made swiftly, demonstrating Zeal Air-Conditioning's commitment to excellence.

The Results

The results were impressive. The new cooling system not only met but exceeded the client’s expectations. Production efficiency improved significantly, and energy consumption was reduced by 25%, contributing to substantial cost savings.

The ability to maintain precise temperature control enhanced product quality, reducing waste and rework rates. The client praised Zeal Air-Conditioning for their innovative approach and technical expertise, marking this project as a resounding success.

Conclusion

This project highlights Zeal Air-Conditioning's capability to tackle complex challenges with tailored solutions. Their success in solving this unique cooling challenge reinforces their reputation as industry leaders in HVAC solutions. By prioritizing collaboration, innovation, and precision, they continue to set new standards in the field.